Authors: J. Hulme, A.H. Sakhaei and M. Shafiee,

Source: Materials Today: Proceedings, https://doi.org/10.1016/j.matpr.2023.02.278

License: This is an open access article under the CC BY 4.0 (http://creativecommons.org/licenses/by/4.0/).

In recent years, 3D printing technology has emerged as a powerful tool in the field of biomedical engineering. One of the most promising applications of 3D printing is in the development of bone scaffolds for tissue engineering. Bone scaffolds are structures that mimic the natural architecture of bone tissue and are used to promote the regeneration of damaged or lost bone tissue.

A recent scientific paper published in the journal “Materials Today” has investigated the use of 3D printing technology to fabricate bone scaffolds using lattice materials. The study showcases the potential of 3D printing in creating customized bone scaffolds with precisely engineered structures and properties that can support bone regeneration.

The research is particularly relevant in the context of bone tissue engineering, as traditional methods of scaffold fabrication have limitations in terms of structural control and customization. The use of 3D printing to create lattice structures enables the design of scaffolds with tailored mechanical properties and optimized pore sizes, which can enhance the integration of the scaffold with the surrounding tissue.

In this post, we will delve into the key findings of this groundbreaking research paper and discuss its implications for the field of tissue engineering. By exploring the potential of 3D printing in creating lattice bone scaffolds, we can advance the development of regenerative medicine and improve the outcomes for patients suffering from bone injuries and diseases.

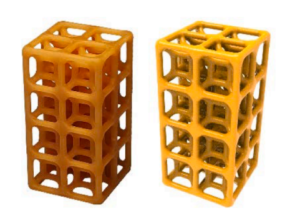

The purpose of this study is to investigate the mechanical performance of lattice material bone scaffolds under compression and observe the relationship of this behavior with respect to different lattice types and porosity. The authors developed the four configurations illustrated in figure 1.

cubic, BCC, BCCZ, and FCC using Fused Filament Fabrication.

Mechanical compression tests were performed on each of the structures as illustrated in figure 2. This test allows extracting results of the maximum load supported by the structure before it fails.

With the results obtained from each test, comparisons were made between the results obtained and thus evaluate which is the most promising configuration for application (see Fig. 3). Emphasizing that only the compressive load was evaluated, we know that the bones are also subjected to tensile, flexion and shear forces.

The figure below illustrates the step-by-step procedure of integrating a lattice-structured bone scaffold into a sample femur bone.

In this post, it was possible to delve into the main findings of this groundbreaking research work and discuss its implications for the field of tissue engineering. By exploiting the potential of 3D printing to create latticework of bone structures, we can advance the development of regenerative medicine and improve outcomes for patients suffering from bone injuries and diseases.

Do you want to know more about the work developed by the authors? Visit the link at the top of this post!

Lightweight and Strong: 3D Printed Lattices – (3dtry.com)