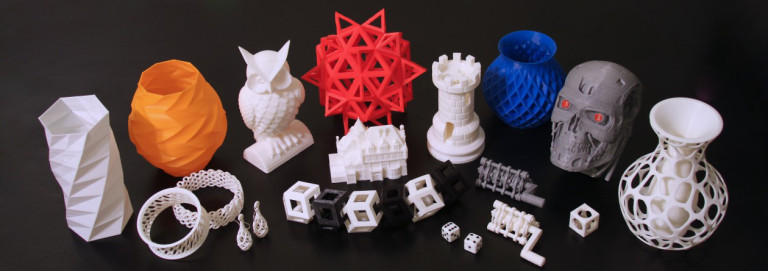

3D printing is an innovative technology that has revolutionized the manufacturing industry. With 3D printing, it is possible to create complex designs and geometries that would be impossible to achieve with traditional manufacturing methods. While 3D printing can be used with a variety of materials, there are some fundamental differences between printing with plastics and metals.

One of the most significant differences between printing with metal and plastic is the cost. Printing with metal is generally more expensive than printing with plastic. The cost of metal 3D printing is determined by several factors, including the type of metal used, the complexity of the design, and the printing process itself. Metal filaments and powders are also more expensive than plastic filaments, which can add to the cost of metal printing.

Another difference between printing with metal and plastic is the size of the objects that can be printed. Printing with metal allows for larger objects to be printed than with plastic, due to the strength and durability of metal. However, the size of the object that can be printed also depends on the printing technology used, as well as the size of the printer bed.

In this post, we will explore the main differences between printing plastics and metals using 3D printing.

Printing with Plastics

Plastic is one of the most popular materials used in 3D printing. There are several types of plastic filaments that can be used in 3D printing, including ABS, PLA, PETG, and Nylon. Here are some of the main differences between printing with plastics and metals:

- Ease of Printing: One of the biggest advantages of printing with plastics is the ease of printing. Plastics can be printed at relatively low temperatures, and the printing process is less complicated than printing with metals.

- Flexibility: Plastics are more flexible than metals, which means that they can be used to create objects that need to be able to bend or flex. This makes them ideal for creating objects such as phone cases, toys, and other objects that need to be durable and flexible.

- Low Cost: Plastics are generally less expensive than metals, which makes them a popular choice for 3D printing. The cost of plastic filaments is relatively low, and the printing process is less expensive than printing with metals.

- Limited Strength: One of the main disadvantages of printing with plastics is their limited strength. Plastics are not as strong as metals, which means that they are not suitable for applications that require high strength or durability.

Printing with Metals

Metal is another popular material used in 3D printing. There are several types of metals that can be used in 3D printing, including stainless steel, titanium, and aluminum. Here are some of the main differences between printing with metals and plastics:

- Strength: Metals are much stronger than plastics, which makes them suitable for applications that require high strength and durability. This is why metals are often used in aerospace, automotive, and other industries where strength is critical.

- High Cost: One of the main disadvantages of printing with metals is the high cost. Metal filaments are more expensive than plastic filaments, and the printing process is more complicated and expensive.

- Complex Printing Process: Printing with metals is more complicated than printing with plastics. Metals need to be printed at higher temperatures, and the printing process requires more precise control over the printing environment. This makes printing with metals more challenging and time-consuming.

- Unique Properties: Each type of metal has its unique properties, which makes them suitable for different applications. For example, titanium is known for its strength, lightweight, and resistance to corrosion, while stainless steel is known for its strength and durability.

Conclusion

In conclusion, there are some fundamental differences between printing with plastics and metals using 3D printing technology. Plastics are easier to print, more flexible, and less expensive, but they are not as strong or durable as metals. Metals are stronger and more durable, but they are more expensive, and the printing process is more complicated. Both plastics and metals have their unique properties, and each material is suitable for different applications.

https://www.linkedin.com/company/3d-try/?viewAsMember=true

Lightweight and Strong: 3D Printed Lattices – (3dtry.com)