3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from digital models. This technology has taken the world by storm, revolutionizing the way we think about design and manufacturing. From aerospace to medicine, 3D printing has made its mark in various industries, promising a future of endless possibilities. But where did it all begin? In this blog post, we’ll explore the origins of 3D printing and how it has evolved over the years.

The idea of 3D printing can be traced back to the 1980s when Chuck Hull, a physicist, invented the first 3D printing technology known as stereolithography (SLA). Hull was working for a company that used UV lamps to coat tables with thin layers of plastic, and he had an idea of using the same process to create 3D objects. Hull developed a process where a UV light was used to solidify a thin layer of liquid plastic, and the process was repeated, layer by layer, until a complete 3D object was created. This was the birth of 3D printing.

The early versions of SLA were not very efficient, and the process was quite slow. However, the potential for the technology was immediately recognized. Soon after, Carl Deckard, a student at the University of Texas, developed another 3D printing technology known as Selective Laser Sintering (SLS). Unlike SLA, SLS used a laser to fuse powdered material together, layer by layer, to create a 3D object. This process was faster and more efficient than SLA, and it opened up new possibilities for 3D printing.

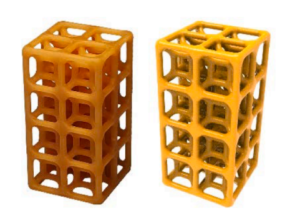

Throughout the 1990s, 3D printing technology continued to develop, with new methods and techniques emerging. In 1992, Scott Crump, a co-founder of Stratasys, invented Fused Deposition Modeling (FDM). FDM is a 3D printing technology that uses a heated nozzle to melt a thermoplastic material, which is then extruded layer by layer to create a 3D object. FDM was a game-changer for 3D printing because it was much cheaper and faster than SLA and SLS.

In the early 2000s, 3D printing technology became more widely available, with new companies entering the market and developing their own technologies. MakerBot, founded in 2009, was one of the first companies to develop a desktop 3D printer that was affordable and easy to use. This made 3D printing accessible to individuals and small businesses, and it paved the way for the growth of the industry.

Today, 3D printing technology has come a long way, and it is used in various industries, including aerospace, automotive, medical, and consumer products. The technology has enabled designers and engineers to create complex geometries that would have been impossible to make using traditional manufacturing methods. It has also enabled the production of customized products, such as prosthetics and dental implants, that are tailored to the specific needs of individual patients.

One of the most exciting developments in 3D printing technology is the ability to print with different materials, including metals, ceramics, and even living cells. This has opened up new possibilities for the technology, including the ability to print functional parts for machines and even human organs for transplant. The potential for 3D printing in the medical field is enormous, with the technology already being used to create personalized implants and prosthetics.

The future of 3D printing is bright, with new developments and breakthroughs being made all the time. One of the most promising areas of research is in the development of new materials that can be used in 3D printing. Researchers are working on developing materials that are stronger, lighter, and more durable, as well as materials that can be used in bioprinting.

In conclusion, the origins of 3D printing can be traced back to the 1980s when Chuck Hull invented the first 3D printing technology, stereolithography (SLA). Over the years, new technologies and methods were developed, including Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM), making 3D printing more accessible and affordable. Today, 3D printing technology has revolutionized various industries and is opening up new possibilities for the future. As the technology continues to develop, we can expect to see even more exciting breakthroughs and developments in the years to come.

https://www.linkedin.com/pulse/revolutionizing-manufacturing-3d-printing-3d-try

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.